PRODUCTION OF SYNTHETIC FABRICS

Manufacturing Process of Rayon

Viscose rayon is obtained from the cellulose of wood pulp or cotton linter. The steps involved are as follows:

(i) Purification: The cellulose (wood pulp or cotton linters) is first purified.

(ii) Acid treatment: The cellulose is then treated with the right chemicals. E.g. caustic soda and carbon-disulphide to form a thick thread-like liquid.

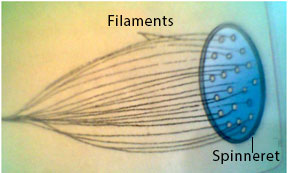

(iii) Spinning: The liquid is then forced through a nozzle containing many fine holes called the rayon filament or fibres are produced.

(iv) Delustering: This is the process of adding a white pigment powder into the spinning solution so that the filament will not have metallic luster.

(v) Dyeing: This may be carried out after the yarn is spun or the dye can be added to the spinning solution.

(vi) Weaving: The spun yarn is woven into a fabric in the process called weaving.

Spinneret with filaments

Manufacturing Procedure of Acetate

(i) The cellulose is purified.

(ii) It is treated with acetic acid and acetic anhydride, then with water.

- NEW: Download the entire term's content in MS Word document format (1-year plan only)

- The complete lesson note and evaluation questions for this topic

- The complete lessons for the subject and class (First Term, Second Term & Third Term)

- Media-rich, interactive and gamified content

- End-of-lesson objective questions with detailed explanations to force mastery of content

- Simulated termly preparatory examination questions

- Discussion boards on all lessons and subjects

- Guaranteed learning